We are proud to announce that EMTD Ltd has been awarded a two year grant from the European Union to undertake a research activity. This is under the Horizons 2020 Clean Sky programme.

EMTD Ltd are leading a project group which includes the following.

EMTD Ltd are leading a project group which includes the following.

Manchester University’s School of Mechanical, Aerospace and Civil Engineering

The Institute of Thermomechanics Academy of Sciences of the Czech Republic (IT ASCR)

Please scroll further down this page for the latest updates –

1st May 2022 – The project has been successfully completed. Our thanks to all involved.

| Call Reference: | H2020-CS2-CFP09-2018-02 |

| Type of Action: | RIA |

| Topic Identification Code: | JTI-CS2-2018-CfP09-ENG-01-39 |

| Topic Title : | Measurement of rotor vibration using tip-timing for high speed booster and evaluation of associated uncertainties |

| Proposal Number/ Acronym: | 862034 / Batista |

| Proposal Title: | Blade Tip Timing System Validator |

Update – 6th December 2019

We’ve been to Manchester University to supply them with a set of blades and a rotor for scanning and modelling. The 29 blades were removed from a Rolls-Royce Viper Engine. This engine was chosen because the blades are made from steel which will allow them to be excited using a magnetic field whilst spinning in the test rig.

Thanks to Ben at Vapourworx surface solutions for the great job of cleaning the blades and disk.

Update – 16th December 2019

We’ve been back to Manchester University to supply them with another set of blades and a rotor for scanning and modelling. We now have three complete rotors from two Viper engines, all with steel blades

Thanks again to Ben at Vapourworx surface solutions for another great job of cleaning the blades and disk.

Update – 29th January 2020

We have returned from a visit to The Institute of Thermomechanics Academy of Sciences of the Czech Republic (IT ASCR) in Prague. The purpose of the visit was to review the test requirements and see the spinning rig first hand. This was a very positive visit and we are on plan to get the Viper Rotor on the rig later this year.

Update – 9th March 2020

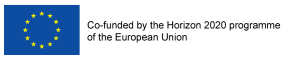

The preliminary blade mode data has been imported into our axial position calculator. This calculator will help determine the axial position of the probes above the blades. For more information see the relevant section of the Editor Manual in the downloads section. There you can also find a sample file for the mode information. This information is subject to change as the project continues.

Update 11th May 2020

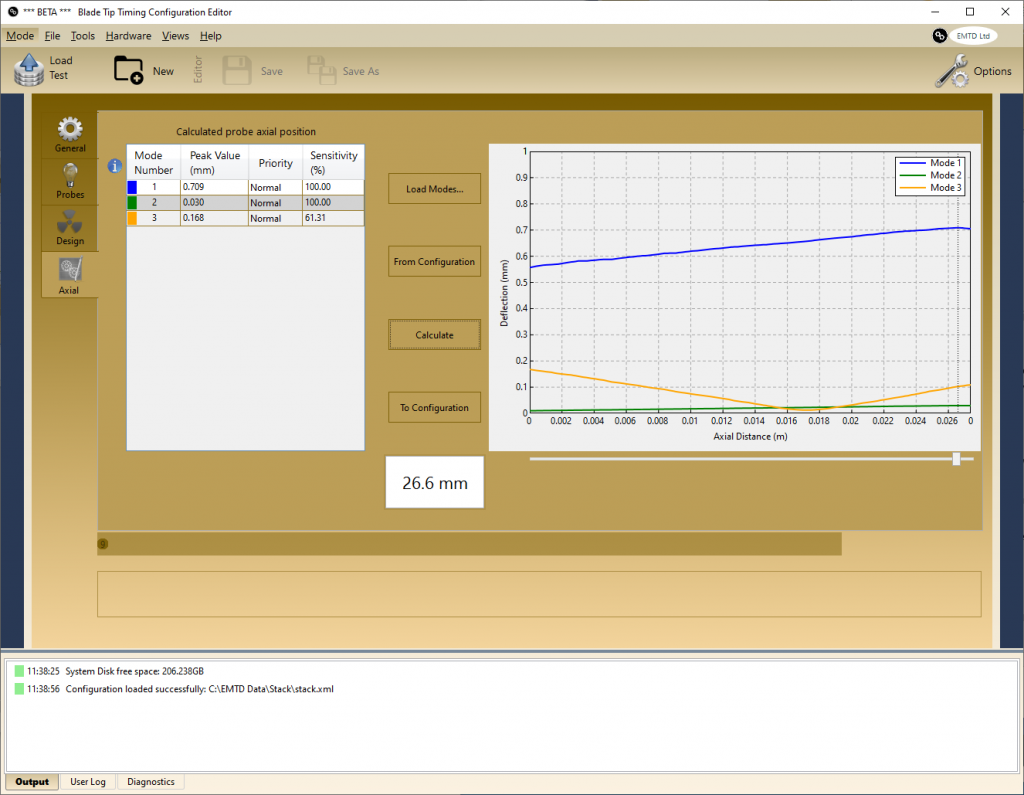

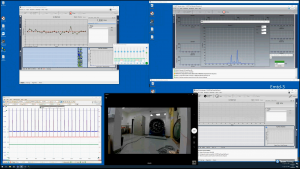

The equipment for Batista is commissioned and undergoing testing. The picture shows the following equipment.

Acquisition, Lasers, Power Supply, simulator and variable reluctance conditioning units. All of this equipment is networked and controllable from MultiTool software. The simulator is driving the laser receivers optically across a small air gap. More information is available on request. enquiries@emtd-measurement.com

Update 4th June 2020

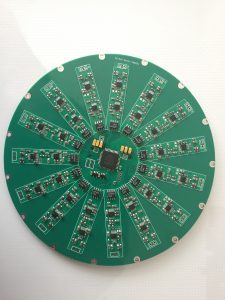

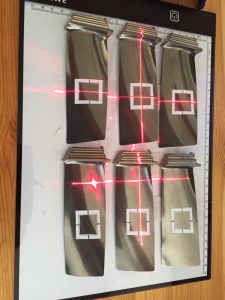

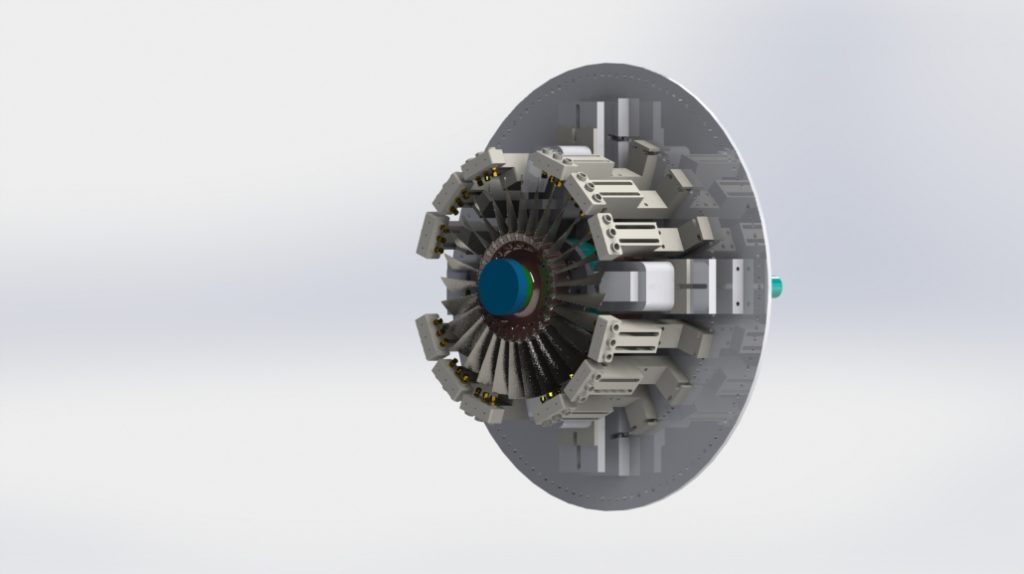

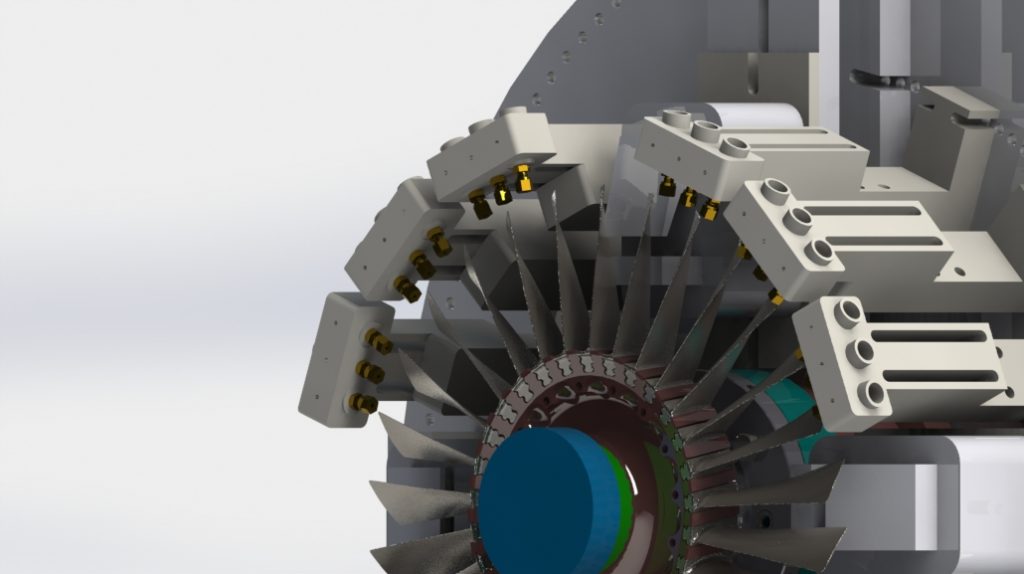

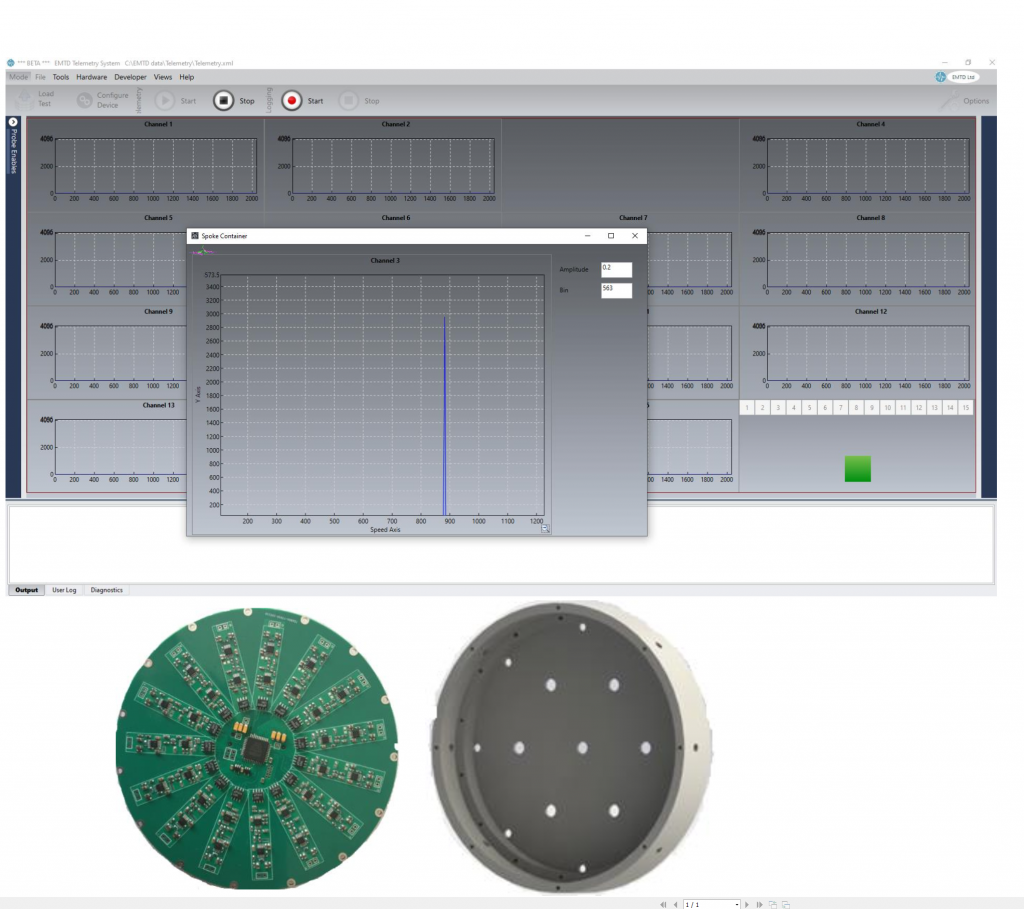

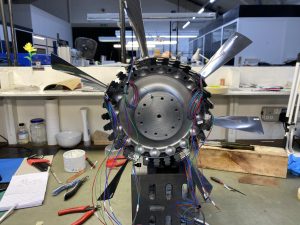

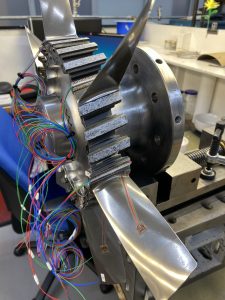

The telemetry system design is complete. We have a custom 15 channel unit designed to interface directly onto the rig. The telemetry for Batista is undergoing commissioning and testing. Below is the PCB for the end of shaft design and this can be seen in the rig adapter design below. The blue area is the telemetry unit. To the right is the blades are marked ready for strain gauge placement.

Status update for the spinning rig in Prague.

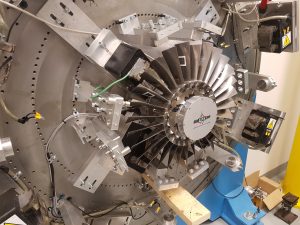

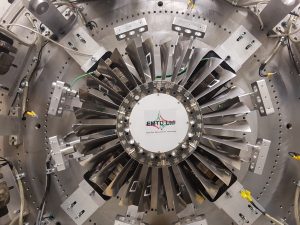

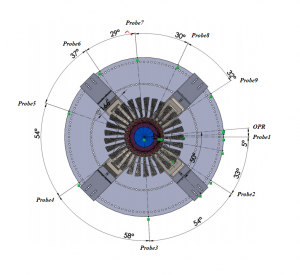

Here is the configuration for the rotor. All of the parts will soon be in manufacture and we can see the multiple probe holders for the various probes and the excitation magnets. We are looking to add more magnets at present.

More information is available on request. enquiries@emtd-measurement.com

Update 29th June 2020

Manchester University remains in lockdown due to Covid-19 but are hoping to open up the labs shortly to continue with the blade calibrations. The telemetry system for Batista is commissioned and undergoing calibration using our bespoke Telemetry acquisition software. More information is available on request. enquiries@emtd-measurement.com

Update 12th August 2020

The blades are back from being strain gauged at Rotadata and we will begin testing with the Telemetry unit shortly.

Update 12th Update September 2020

Manchester University has resumed work on blade calibration after being unable to access their labs during the lockdown. We visited last week to witness the blade calibration process before the calibration work begins in earnest. We are using the strain gauged blades from the Viper engines.

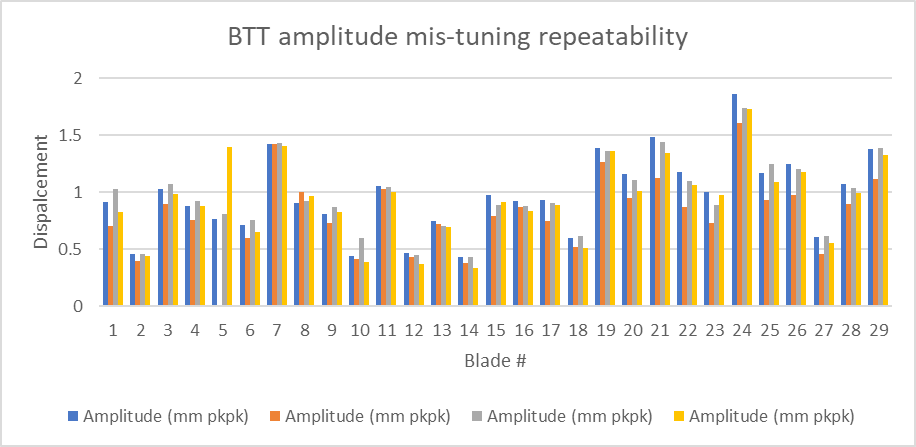

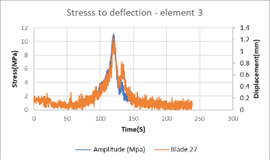

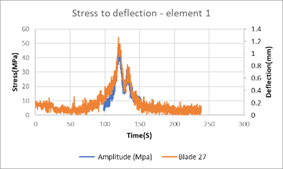

The blades are clamped into a vice at the root and then excited via a chopped air jet. The blade response is recorded via a strain gauge system for each of the first three modes. Two cameras are also being used to measure the peak displacement at the end of the blade and to determine mode shapes. This will give us the stress to deflection ratios for the first three modes which we need for the Tip Timing system to be able to measure blade stress.

A slow motion video has been uploaded to our YouTube Channel

Update January 2021

Update February 10th 2021

Update 6th April 2021

Update 27th April 2021

The Institute of Thermomechanics Academy of Sciences of the Czech Republic (IT ASCR)

Update 22nd May 2021

The Institute of Thermomechanics Academy of Sciences of the Czech Republic (IT ASCR)

Update 12th August 2021

The probes have been positioned taking into account all of the fixed hardware present on the rig. Our software has determined the best locations given these restrictions to maximise sensitivity to the blades expected modes of vibration.

Further Update

The probes are fitted and awaiting final adjustment. We are connecting the Telemetry unit and preparing for the first check run in the next few days.

Update 26th August 2021

Update 27th August 2021

Update 30th August 2021

Update 1st November 2021

![]()